Space available for the project was extremely limited, making it necessary to build several retaining structures having heights of up to 17 m almost vertically. High vertical pressure on top of the structure from traffic loads in excess of 400 kPa very close to the edges had to be accommodated and peak ground acceleration (PGA) of 0.145 g had to be considered.

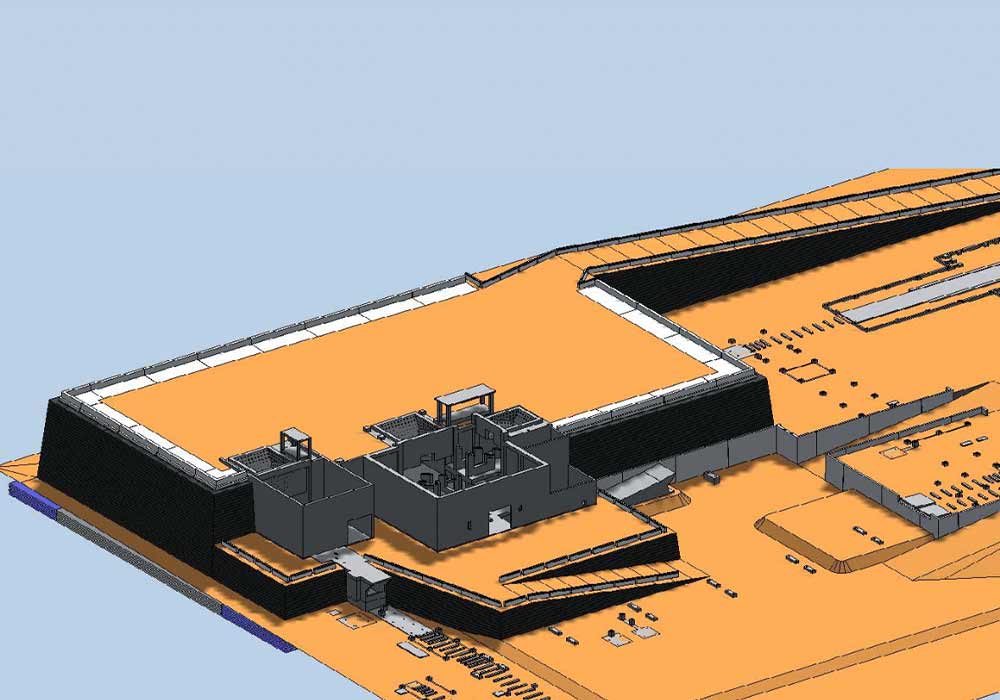

Originally, the plan was to use concrete cantilever walls to provide this support but owing to the cost and complexity of these structures combined with the >10 m wall height, this original solution was discarded early in the project. Ultimately, the option selected was the economically viable geogrid reinforced soil retaining wall system, using EnkaGrid PRO uniaxial geogrids with tensile strength varying from 60 kN/m up to 180 kN/m. The surface area for the reinforced structure was divided into 15 geotechnical sections to facilitate a variety of calculations. Soil excavations and investigations on the site were performed and reported on, indicating that a layer of limestone bedrock was encountered at a more or less uniform depth, on average 2.0 m from the surface in all sections. Loose granular soil located above this layer was replaced and reinforced with EnkaGrid MAX 60 biaxial geogrid only under the toe of the structures. The planning assignment prepared was based on EC 7 and related European geotechnical standards, including those pertaining to the internal and external stability of the structures.

Using Enka Solutions, the contractor was able to make maximum use of the available space to achieve a more economical construction when compared to other options. The construction of the areas for the limestone crushers intended to supply the increased capacity of the expanded factory was successfully completed. Before the construction, the cement plant produced 1,500 tons of cement per day, whereas the total capacity of the extended plant, complete with crusher and new silos, was now increased to 7,700 tons.

EnkaMat is a flexible threedimensional mat for immediate, permanent erosion protection on many different slope types. Its unique structure creates an artificial root structure that prevents soil erosion from steep slopes, river banks, landfill containments and other vulnerable areas. EnkaMat has excellent soil retention, providing the perfect conditions for vegetative root systems to develop. Embedded with soil, it forms an integrated and fully vegetated system to control erosion.

Consistent and excellent long-term performance is a key feature of the EnkaDrain drainage mat. Each variant has a drainage core bonded to a synthetic nonwoven geotextile layer or is sandwiched between two such layers. EnkaDrain provides solutions for groundwater issues for civil engineering and building projects, both during construction and in service. With an extensive portfolio of product types, EnkaDrain is suitable for many different applications.

The EnkaGrid product range comprises a large portfolio of rigid geogrids, their common values being the optimum soil-grid interaction delivered for each application in any soil type and their outstanding mechanical longterm durability. EnkaGrid types are uni-axial or bi-axial and manufactured from laser welded strips. A high strength grid composite of aramid mesh and a thermally bonded nonwoven is available for the most demanding projects.

When the sub-grade of a construction site is too weak to bear normal construction activity, Colbonddrain will speed up consolidation considerably. Colbonddrain is a tough and durable prefabricated vertical drain (PVD), designed to extract pore water from soils to achieve 90% consolidation within six months. Thanks to its high performance Colbonddrain is often the chosen PVD for major, technically demanding projects.

The high modulus multifilament yarns used in the production of Enka-Force fabrics offer excellent creep characteristics, making them the perfect choice for use in soil reinforcement applications.The range has been specifically designed to exhibit high strength at low elongation. Typical areas of application include reinforced soil walls, embankments on weak soil and load transfer platforms.